Sanyo Pancake Stepper Motor with Encoder: Bipolar, 200 Steps/Rev, 42×24.5mm, 3.5V, 1 A/Phase, 4000 CPR

Tutti i prezzi sono IVA inclusa

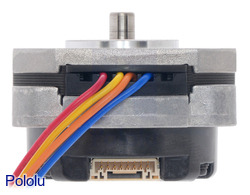

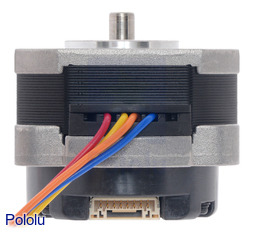

This NEMA 17-size pancake bipolar stepping motor from Sanyo features an integrated high-resolution (1000 P/R) quadrature encoder that allows for 4000 counts per revolution of the output shaft when counting both edges of both channels. The stepper motor itself has a 1.8° step angle (200 steps/revolution) and each phase draws 1 A at 3.5 V, allowing for a holding torque of 0.85 kg-cm (12 oz-in).

|

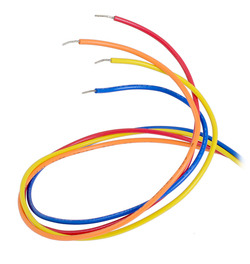

Bipolar stepper motor wires are terminated with bare leads. |

|---|

|

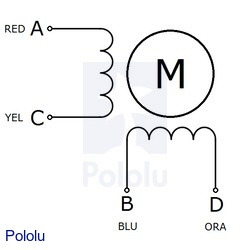

Sanyo bipolar stepper motor wiring diagram. |

|---|

Overview

This NEMA 17-size pancake bipolar stepping motor from Sanyo features an integrated high-resolution (1000 P/R) quadrature encoder that allows for 4000 counts per revolution of the output shaft when counting both edges of both channels. The stepper motor itself has a 1.8° step angle (200 steps/revolution) and each phase draws 1 A at 3.5 V, allowing for a holding torque of 0.85 kg-cm (12 oz-in). The motor has four color-coded wires terminated with bare leads: red and yellow connect to one coil; orange and blue connect to the other. It can be controlled by a pair of suitable H-bridges (one for each coil), but we recommend using a bipolar stepper motor driver or one of our Tic Stepper Motor Controllers. In particular, the Tics make control easy because they support six different interfaces (USB, TTL serial, I²C, RC, analog voltages, and quadrature encoder) and are configurable over USB with our free configuration utility.

Our 5 mm universal mounting hub can be used to mount objects on the stepper motor’s 5 mm-diameter output shaft, and our NEMA 17 aluminum bracket offers a variety of options for mounting this stepper motor in your project.

This stepper motor is also available without an encoder.

Specifications

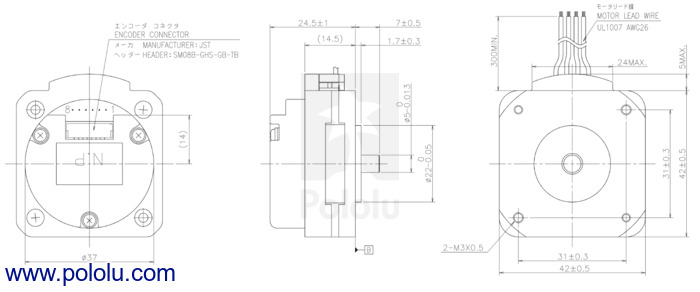

- Size: 42 mm square × 24.5 mm, not including the shaft (NEMA 17)

- Weight: 105 g (3.7 oz)

- Shaft diameter: 5 mm

- Steps per revolution: 200

- Current rating: 1 A per coil

- Voltage rating: 3.5 V

- Resistance: 3.5 Ω per coil

- Holding torque: 850 g-cm (12 oz-in)

- Inductance: 1.2 mH per coil

- Lead length: 30 cm (12″)

- Output shaft supported by two ball bearings

More specifications are available in the SS242x stepper motor datasheet (385k pdf) and the product-specific SS2421-50XE100 datasheet (568k pdf).

Dimensions

|

Dimensions (in mm) of the SS2421-50XE100 42×24.5mm Sanyo pancake stepper motor with encoder. |

|---|

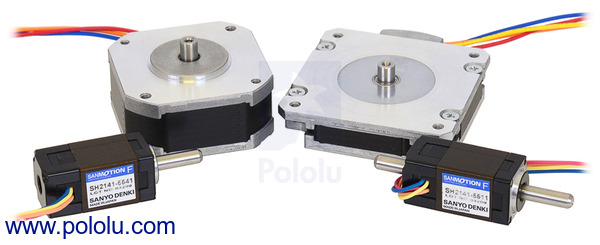

We also carry a taller version of this stepper motor with identical dimensions except for the height. The pictures below show this stepper motor on the left and the taller version on the right:

|

|

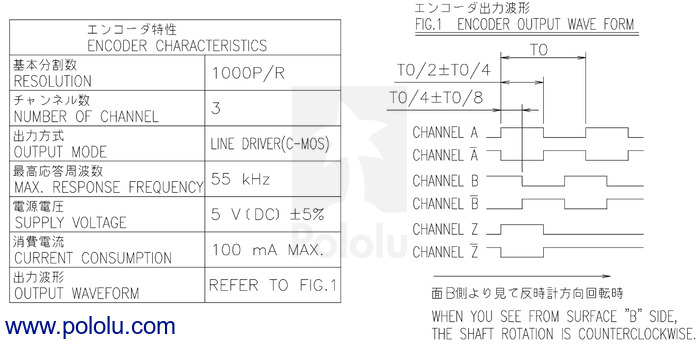

Quadrature encoder

|

The integrated quadrature encoder operates from 5 V and has a resolution of 1000 P/R, which allows for 4000 counts per revolution (CPR) of the output shaft when counting both edges (i.e. rising and falling) of both channels (i.e. A and B). In addition to the A and B channel outputs, the encoder has a home channel, Z, that pulses once per revolution and can be used for absolute positioning. The encoder also has outputs for the inverse of A, B, and Z. A 15 cm (6″) encoder cable is included.

|

|

|

|

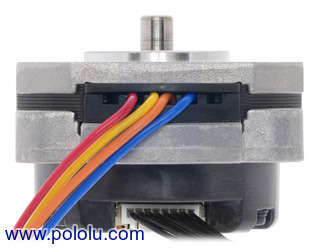

Bottom view of the 42×24.5mm Sanyo pancake stepper motor with encoder. |

|---|

Stepper Motor Applications

Stepper motors are generally used in a variety of applications where precise position control is desirable and the cost or complexity of a feedback control system is unwarranted. Here are a few applications where stepper motors are often found:

- Printers

- CNC machines

- 3D printer/prototyping machines (e.g. RepRap)

- Laser cutters

- Pick and place machines

- Linear actuators

- Hard drives

|

Sanyo stepper motors; from left to right: 14mm single shaft, 42×18.6mm, 50×11mm, 14mm double shaft |

|---|

Note: Sanyo Denki calls this product the “SANMOTION F2 STEPPING SYSTEMS TYPE SS2421-50XE100”.