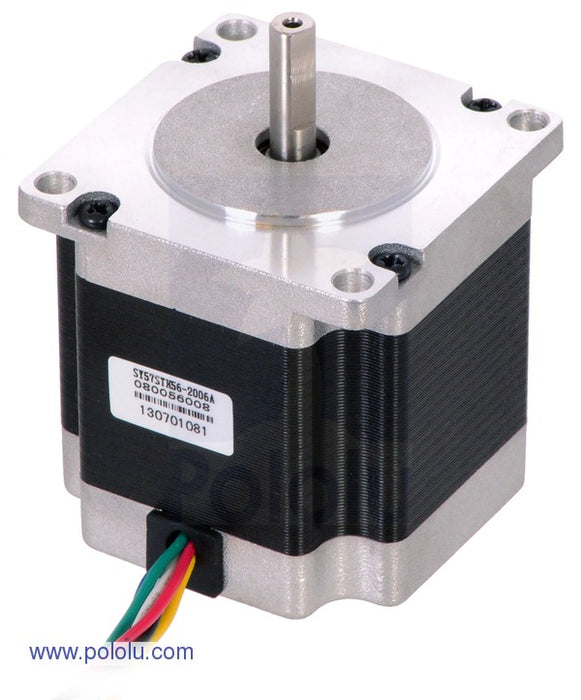

Stepper Motor: Unipolar/Bipolar, 200 Steps/Rev, 57×56mm, 3.6V, 2 A/Phase

All prices are VAT included

This NEMA 23-size hybrid stepping motor can be used as a unipolar or bipolar stepper motor and has a 1.8° step angle (200 steps/revolution). Each phase draws 2 A at 3.6 V, allowing for a holding torque of 9 kg-cm (125 oz-in).

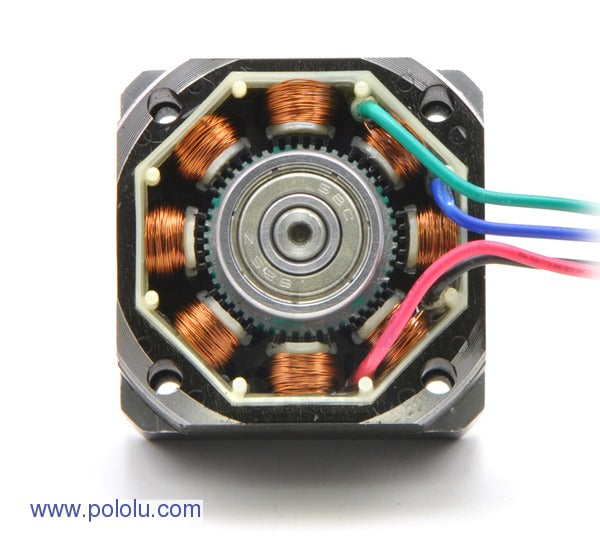

This high-torque hybrid stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 2 A at 3.6 V, allowing for a holding torque of 9 kg-cm (125 oz-in). The motor has six color-coded wires terminated with bare leads that allow it to be controlled by both unipolar and bipolar stepper motor drivers. When used with a unipolar stepper motor driver, all six leads are used. When used with a bipolar stepper motor driver, the center-tap yellow and white wires can be left disconnected (the red-blue pair gives access to one coil and the black-green pair gives access to the other coil). We recommend using it as a bipolar stepper motor.

Specifications

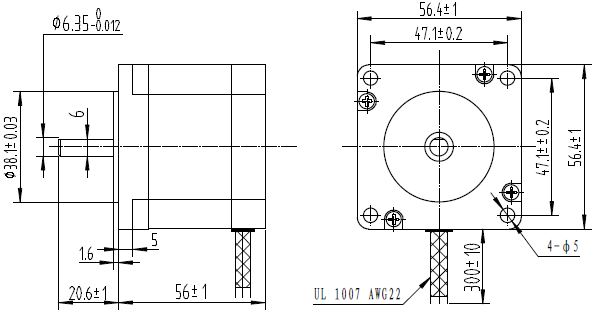

- Size: 56.4 mm square × 56 mm, not including the shaft (NEMA 23)

- Weight: 0.7 kg (25 oz)

- Shaft diameter: 1/4″ (6.35 mm) “D”

- Steps per revolution: 200

- Current rating: 2 A per coil

- Voltage rating: 3.6V

- Resistance: 1.8 Ohm per coil

- Holding torque: 9 kg-cm (125 oz-in)

- Inductance: 2.5 mH per coil

- Lead length: 12 in

More specifications are available in the datasheet (49k pdf).

Stepper Motor Applications

Stepper motors are generally used in a variety of applications where precise position control is desirable and the cost or complexity of a feedback control system is unwarranted. Here are a few applications where stepper motors are often found:

- Printers

- CNC machines

- 3D printer/prototyping machines

- Laser cutters

- Pick and place machines

- Linear actuators

- Hard drives