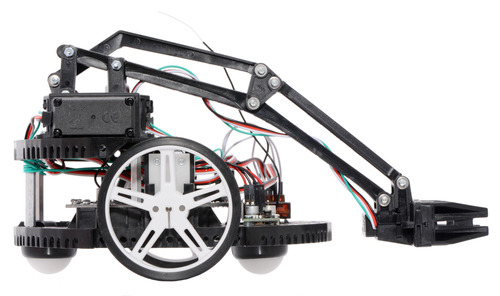

Empower your Romi robot to manipulate its surroundings with this robotic arm accessory kit! The kit contains everything you need to build the arm, including a micro gripper and three servos—one for controlling the height of the arm, one for controlling the tilt of the gripper, and one for actuating the gripper paddles themselves. All three servos are specially modified to provide access to their feedback potentiometers, enabling higher-level closed-loop control of all three joints.

Overview

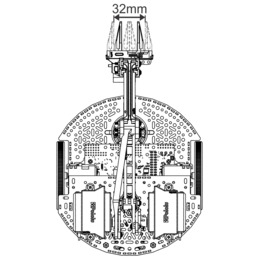

This Robot Arm Kit is an accessory for the Romi Chassis that allows it to manipulate small objects around it. The kit includes a micro gripper with paddles that can slide up to 32 mm apart, arm linkages for supporting the gripper, and a platform to mount everything to. The assembly is actuated by three included servos that are specially modified to provide access to their feedback potentiometers through a fourth (green) wire, which lets you detect if something is interfering with their ability to get to their commanded positions. This feedback also enables more complex closed-loop control of the arm from your main controller.

|

The Romi arm mounts on the rear half of the Romi chassis, just above the motors, using the included aluminum standoffs. Two standard-size servos sit at the base of the arm and control the height and tilt angle of the micro gripper while a micro servo is housed inside the gripper to actuate the paddles themselves. The larger lift and tilt servos can briefly draw up to around 1.8 A each when commanded to move abruptly, but the typical current draw should be under an amp each. The stall current of the micro gripper servo is approximately 0.8 A at 6 V. All three servos are intended to be powered from 4.8 V to 6 V (nominal) battery packs or a suitable power supply in that general range. For each servo, there is an approximately 1:1 correspondence between the servo position in milliseconds and the feedback voltage in millivolts, so for example, the feedback voltage will be around 1.5 V at the position corresponding to 1.5 ms servo pulses.

|

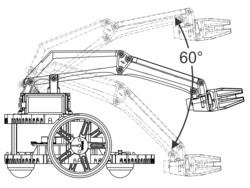

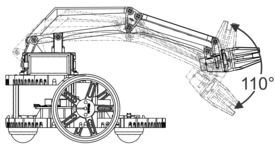

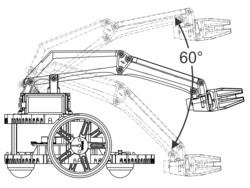

Range of motion of the height of the Robot Arm for Romi. |

|---|

|

|

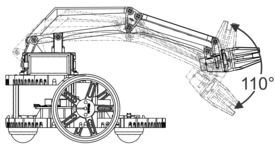

Range of motion of the wrist tilt on the Robot Arm for Romi. |

|---|

|

|

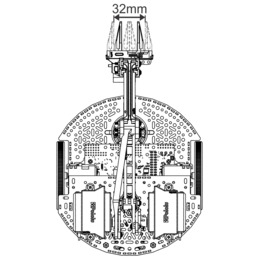

Range of motion of the gripper on the Robot Arm for Romi. |

|---|

|

The gripper, which can be mounted to the end of the arm in either a horizontal (scoop) or vertical (crane) orientation, uses a rack and pinion design with the pinion gear mounted to the servo spline and opposing racks to keep the gripper paddles synchronized and parallel to each other throughout the range of motion.

|

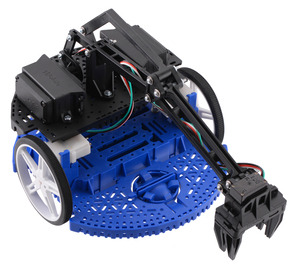

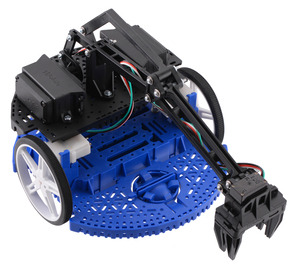

| Romi arm with horizontal gripper orientation installed on a Romi.

|

|---|

|

|

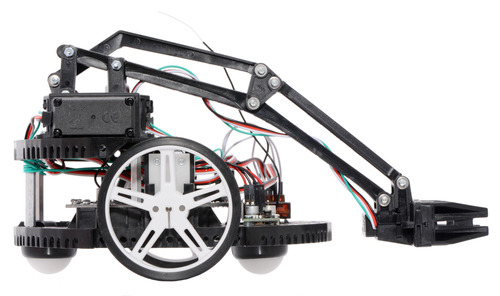

Romi arm with vertical gripper orientation installed on a Romi. |

|---|

|

The maximum recommended payload of the arm is 3.5 oz (100 g), and the gripper can open to a maximum width of 32 mm. Please note that the full range of motion of the gripper servo requires pulses beween 0.5 ms (fully open) to 2.4 ms (fully closed), which well beyond the standard hobby servo range of 1 ms to 2 ms, so you should make sure your control electronics is capable of generating such signals if you care about getting the full range.

Note: Even though most of the arm's weight is positioned in the back of the chassis, lifting objects will generally cause the Romi to tilt forward, so we strongly recommend adding a second ball caster to the optional ball caster spot on the front of the Romi . You can use a rubber band to stiffen the suspension of this ball caster if desired (see the user's guide for more information).

For assembly instructions and more details about using the Robot Arm for the Romi, see the Robot Arm for Romi User's Guide

We are working on electronics to simplify integrating this arm into your Romi robot, but we did not want that to hold up releasing the arm itself for ambitious users with the skills to assemble their own electronics for powering and controlling the arm. For now, this accessory is intended for advanced users.

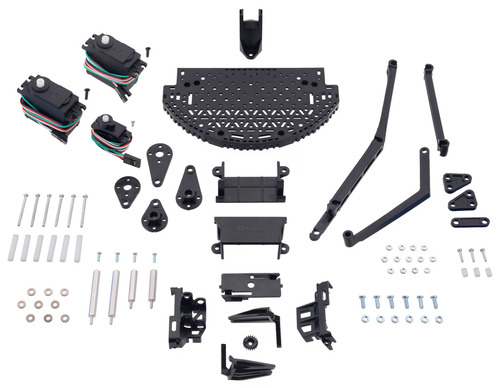

Kit contents